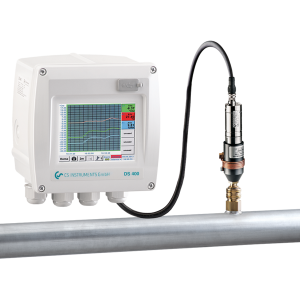

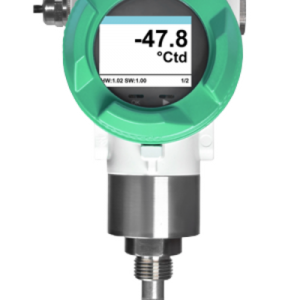

FA 510/515 – Dew point sensor for adsorption dryers

Dew point sensor FA 510/515 from -80 to 20°Ctd

In addition to the previously common 4…20 mA analogue output the new generation of dew point sensors have a digital RS 485 interface (Modbus-RTU). All values like e. g. dew point, temperature, absolute humidity … which are measured and calculated by the dew point sensor can be retrieved via the Modbus protocol.

Compared with the previous models the sensorics and evaluation electronics have been improved once again, especially the integrated temperature compensation. This means: Increased accuracy at different ambient temperatures and an improved resolution of the sensor signal. Like the previous models the new dew point sensors have an excellent long-term stability and show reliable measured values. The sensor element is insensitive against condensation and due to the serial sintered cap made of stainless steel it is protected against direct contact with soiled particles.

Special features of dew point sensor FA 510/515 for desiccant driers:

- Measuring range -80…20°Ctd

- Analogue output 4…20 mA

- Precise, long-term stability

- Condensation insensitive

- Quick response time

- Pressure-tight up to 350 bar (special version

- NEW: Modbus-RTU interface

- NEW: Higher resolution of the sensor signal due to improved evaluation electronics

- Sensor diagnosis on site by means of hand-held instrument or CS Service Software

APPLICATIONS

- Residual moisture measurement in fuel gases

- Dew point measurement in compressed air systems

- Dew point measurement during the spray-painting process

- Dew point measurement in PET bottle production

- Dew point measurement after refrigerant dryer

- Dew point measurement / Dryer control of desiccant dryers

- Dew point monitoring in the pneumatic conveying of powder

- Mobile dew point measurement when servicing dryers

- Dew point on high-pressure systems and in respiratory air

- Dew point monitoring of thermal processing furnaces

- Dew point measurement for nitrogen or oxygen generators

- Moisture and oil measurement during wire drawing and cable production

- Dew point monitoring in the fruit and vegetable sector

- Dew point sensors for ozone generators

- Humidity and quality measurement when generating compressed breathing air

- Dew point monitoring in plastic granulate dryers

- Dew point monitoring of medical compressed air