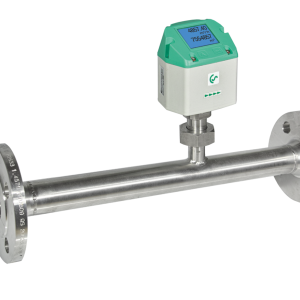

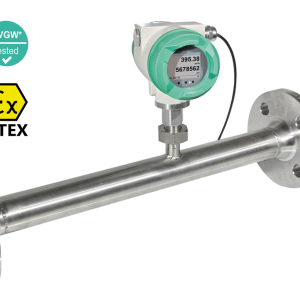

VD 500 – Flow sensor for wet compressed air

Reduce your energy costs and increase your efficiency with the VD 500. Suitable directly for measurement after the compressor. Monitor the delivery rate of your compressor and create a FAD analysis.

Field of application:

- Measuring directly after the compressor

- Measuring at high temperatures

- Measuring fast processes

Advantages of the differential pressure sensor VD 500:

- Proven measuring principle by measuring the differential pressure (dynamic pressure)

- Pressure and temperature compensated, thus output of the standard volume flow rate

- Particularly suitable for extremely high flow rates

- Extremely fast response time of 100 ms

- Quick and easy installation via a ½” ball valve

- No moving parts, therefore low maintenance effort

- Negligible low pressure loss due to negligible low blockage of the diameter

- Applicable for wet and hot compressed air directly after the compressor

Typical applications:

- Measurement of the delivery quantity of compressors

- Compressed air audits

- Efficiency measurement of compressed air systems

Installation conditions:

- After working water separator

- In horizontal lines (recommended) or in risers

Technical details:

- 04…20 mA, pulse and a Modbus RTU (RS 485) interface as standard

- Optional interfaces like Modbus TCP (Ethernet), PoE, M-Bus

- Pressure range up to 20 bar

- Temperature range up to 180°C

- Integrated display to show the measured values

- Available from DN20 to DN500

- Easy installation under pressure

- Settings adjustable via the keys of the display

- Main counter reading can be reset via the display

- Can be used for velocities up to 600 Nm/s

- High accuracy with 1.5% deviation of the measured value

APPLICATION

- Underwater Noise Protection / Bubble Curtain

- Efficiency-FAD analysis for compressors

- Flow meters for professionals – optionally with ATEX approval

- Flow meters for oxidizing gases

- Consumption sensors and flow meters for inert gases

- Flow meters for toxic and corrosive gases

- Consumption meter for oxygen, hydrogen, carbon dioxide

- Consumption meter for nitrogen in tire vulcanization

- Consumption meter for gas measurement in the aerospace industry

- Flow and consumption meter for gas measurement in the automotive industry

- Consumption meter for gas measurement in metal processing

- Consumption sensor for flow measurement of oxygen

- Consumption meter for argon and nitrogen in chemistry

- Nitrogen consumption measurement in the food industry

- Inline consumption meter for nitrogen generators

- Flow measurement in gas mixtures as source gas

- Food gas measurement

Measurement of the flow rate in a compressed air production line in the cosmetics sector