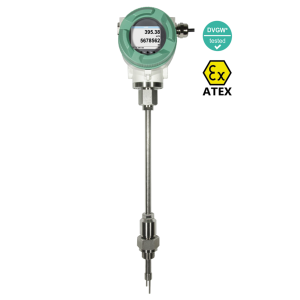

VA 570 – Thermal mass flow meter for consumption measurement

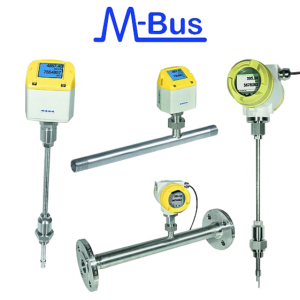

Flow meter with integrated measuring section for compressed air and other gases

Measure and reduce your energy costs and increase your sustainability with the VA 570 flow meter. Monitor your consumption and analyze your leakage rate with a stationary flow meter in distribution stations, in front of individual departments or for billing purposes of individual consumers.

Advantages of the VA 570 flow meter at a glance:

- Measurement of mass flow, direct output of standard volume flow, without additional measurement of pressure and temperature, possible

- All wetted parts of the VA 570 are made of stainless steel, especially for applications with high demands on cleanliness and surface quality

- The robust aluminum housing is ideally suited for harsh industrial conditions as well as for outdoor installations

- No moving parts, therefore low maintenance

- Vanishingly low pressure loss due to vanishingly low blockage of the diameter

- ATEX or DVGW certification available, thus recommended for gases such as natural gas, hydrogen, biogas, etc.

- Highly accurate at small as well as large flow rates

- Pressure and temperature compensated by the thermal mass flow principle

- Easy installation and removal of the sensor from the measuring section, the measuring section can remain in the line for cleaning or recalibration of the sensor and can simply be closed with a sealing cap

Technical details:

- For velocities up to 224 Nm/s

- Temperature range up to a maximum of 180°C

- Maximum pressure 16 bar, up to 40 bar in PN 40 special version

- Can be used from DN15 to DN 80

- Highly accurate with a precision of ±1.5% or ±1% of the measured value, as well as ±0.3% of the full scale

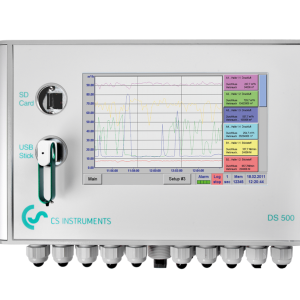

- 04…20 mA, pulse and one Modbus RTU (RS 485) interface as standard, optional interfaces like two galvanically isolated analog outputs (04…20 mA), Modbus TCP (Ethernet), PoE, M-Bus

- Pressure range up to 40 bar

- IP 67

- Integrated display for showing the measured values

- Settings can be changed via the keys on the display

- Total counter reading can be reset via the display

APPLICATION

- Underwater Noise Protection / Bubble Curtain

- Efficiency-FAD analysis for compressors

- Flow meters for professionals – optionally with ATEX approval

- Flow meters for oxidizing gases

- Consumption sensors and flow meters for inert gases

- Flow meters for toxic and corrosive gases

- Consumption meter for oxygen, hydrogen, carbon dioxide

- Consumption meter for nitrogen in tire vulcanization

- Consumption meter for gas measurement in the aerospace industry

- Flow and consumption meter for gas measurement in the automotive industry

- Consumption meter for gas measurement in metal processing

- Consumption sensor for flow measurement of oxygen

- Consumption meter for argon and nitrogen in chemistry

- Nitrogen consumption measurement in the food industry

- Inline consumption meter for nitrogen generators

- Flow measurement in gas mixtures as source gas

- Food gas measurement

Measurement of the flow rate in a compressed air production line in the cosmetics sector